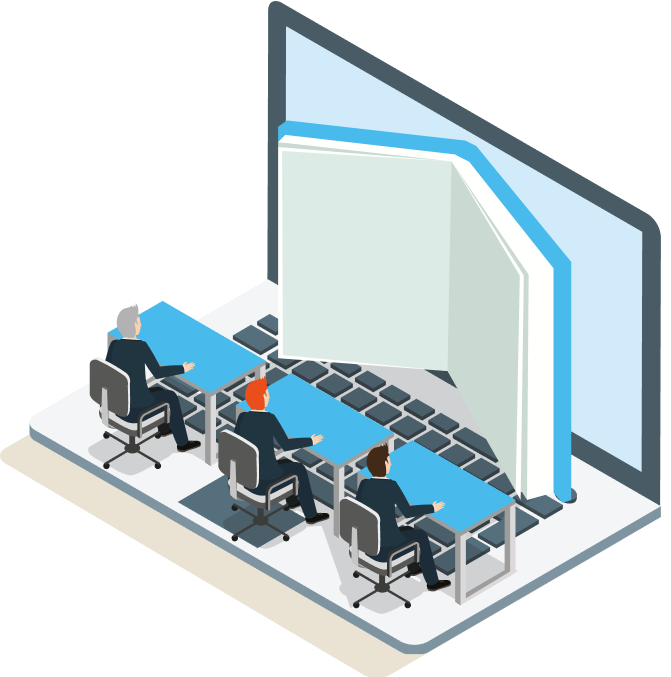

IronLinx Fulfillment is an e-commerce-focused order fulfillment provider based in Kennett Square, PA.

In January 2021, IronLinx hit an unexpected operational snag. As both SKU counts and order volume grew, the processes which IronLinx had put in place a few months before in response to a prior surge suddenly became less effective – with key performance indicators (KPIs) like daily order output per worker experiencing notable declines.

On the surface, IronLinx’s existing system made a lot of sense. In e-commerce, as in many other facets of life, Pareto distributions (the well-known 80/20 rule) are common. Accordingly, IronLinx had designed its processes to physically place critical, fast-moving SKUs immediately behind shipping stations so that picking, packing, and shipping could be handled by the same worker.

When the typical IronLinx customer shipped between 500-2000 orders per day, this process was very effective; however, as several customers scaled and each consistently hit 4000-5000 orders per day, the process became bottlenecked.

A few problems: